Reliability and correctness of settlements between the recipient and the seller of used car catalysts depends on a reliable and correct result of the determination of the content of particular elements in the material supplied. The basic and the fastest technique for this purpose is X-ray fluorescence spectroscopy (or XRF), routinely performed in our laboratory. In order to ensure the highest quality of our services to confirm the obtained results, we also use the inductively induced plasma mass spectrometry technique, abbreviated as ICP-MS. The ICP-MS technique for commercial use was introduced less than 40 years ago. It is characterized by high sensitivity, selectivity, low limit of determination and speed of determinations. It also allows the simultaneous determination of many elements – both on the level of macronutrients and trace contents. However, it is a relatively expensive technique, requires specialized personnel and appropriate methods of sample preparation as well as time necessary for such sample preparation.

Preparation of the sample (reconstitution of the whole mass of the sample taken for testing) to be carried out in a solution that can be analyzed by ICP-MS is a separate issue. The sample is first weighed using an accurate analytical balance and then flooded with a mixture of acids. In this mixture the process of slow dissolution of the sample takes place. If we wanted to wait in conditions of the environment for the complete dissolution of the samples, this process could take up to half a year. Therefore – for acceleration – we support the operation of microwaves, in a special device – a microwave mineralizer. Microwave mineralizer works very similar to the microwave oven used in homes. In the tightly closed vessels, the microwaves accelerate the process of dissolving the sample, which is additionally supported by increasing pressure and temperature. As a result, the sample dissolution process is accelerated, and after dilution, the sample (and in fact the sample solution) is ready for analysis using the ICP-MS technique.

Jak zbudowany jest ICP-MS?

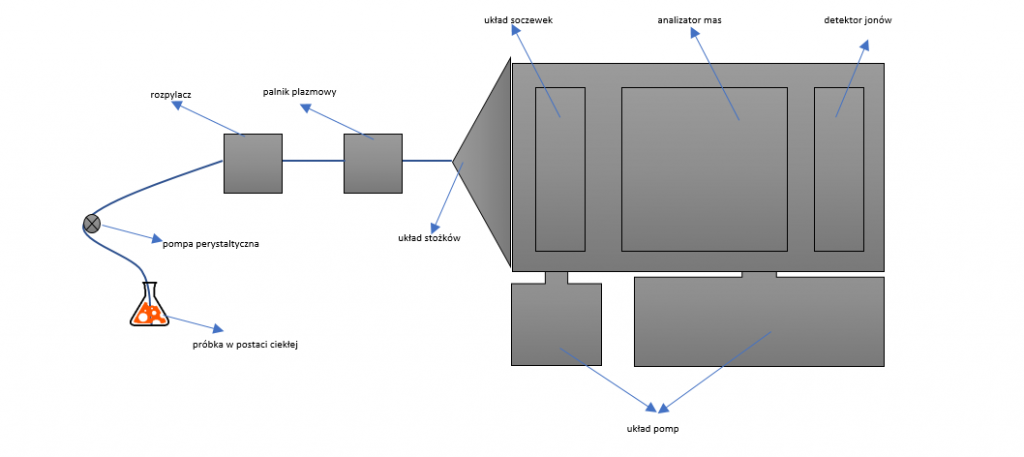

In order not to get too much into the design details – it consists of the following elements, schematically shown in Figure 2, of which the most important are: sample atomizer –

- the task of carrying out the analyzed solution into a spray form, i.e. a suspension of small drops. Most often, this is a solution that uses a suitable high-pressure gas, which causes the liquid droplets to be “tapped” by the gas stream. plasma torch – an induction heated plasma. The name comes from the fact that

- the plasma source is powered by electric voltages, inductively generated by time-varying electromagnetic fields. The temperature reached by the plasma – in our case it is an argon plasma, i.e. “burning” argon is about 6000K ÷ 10000K, which is comparable with the temperature that is on the surface of the Sun. At this temperature, the solvent evaporates and the ionization of the particles, i.e. their break down into an ionic form. Yes, the elements contained in the sample are “broken up” in a way like ions.

Our camera still has such a special window through which you can “peek” during work, what the burning plasma looks like, what color and shape it has, and thus have visual control over the correctness of plasma combustion, without opening the entire spectrometer.

- cone system – the task of this system is to separate the ions from the plasma, i.e. the resulting ions from excess argon and in the most effective way transfer these ions to the interior of the mass spectrometer system, while reducing the pressure. Cones – for the system to work in an efficient and repeatable way, it must be made of appropriate material, and in everyday work pay attention to their cleanliness (dirt causes a decrease in the sensitivity of the apparatus and efficiency of work).

- lens system – after passing through the cone system, the ion beam must be properly focused. And this is the task of the optical system. In addition, the ions (charged particles) separate from the neutral particles here.

- mass analyzer – is the “heart” of the entire system – separating the ion beam according to the value of the mass-to-load ratio (m / z). Thanks to this element, it is possible to separate the individual ions accurately (for simplicity, we can say that the separation of individual elements) in a complex mixture, which is the catalyst matrix. In the ICP MS system, such analyzers as: quadrupole, time of flight, with the magnetic sector and electromagnetic (ie with double focusing) can be used. Our system uses a quadrupole analyzer, one of the most commonly used mass analyzers.

- ion detector – its task is to “see” what is analyzed in the analyzer, i.e. the registration of ions passing through the analyzer. Thanks to the work of the ion detector, it is possible to perform not only a qualitative analysis (determination whether there is palladium, rhodium or platinum present in the catalyst sample), but also to perform quantitative analysis – that is, to determine exactly how many elements are present in the sample.

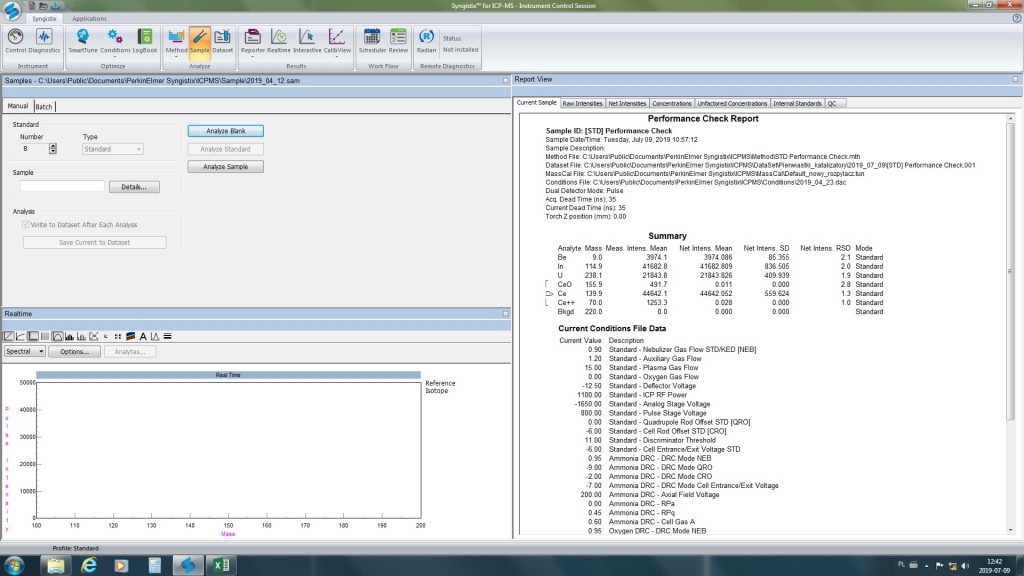

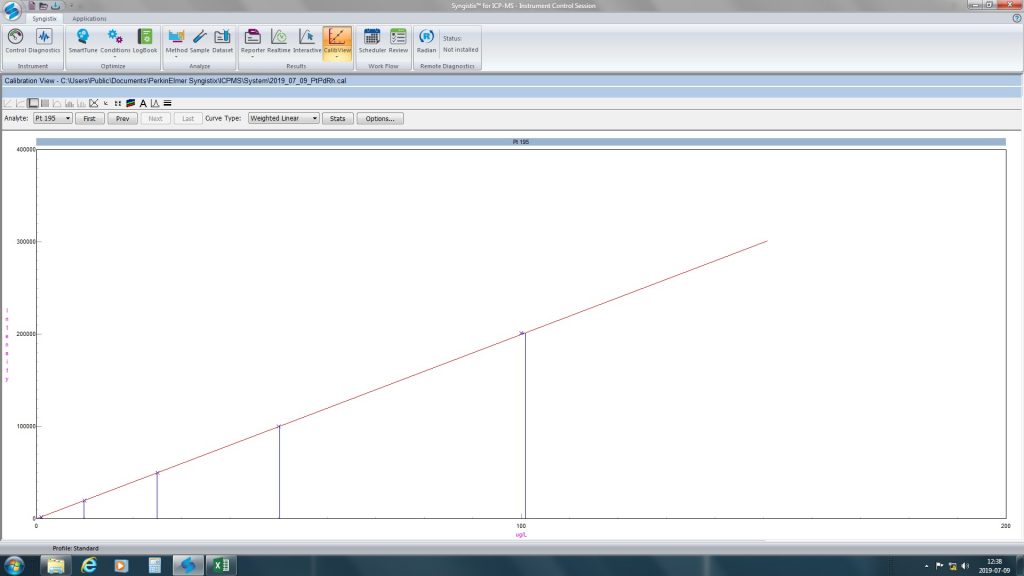

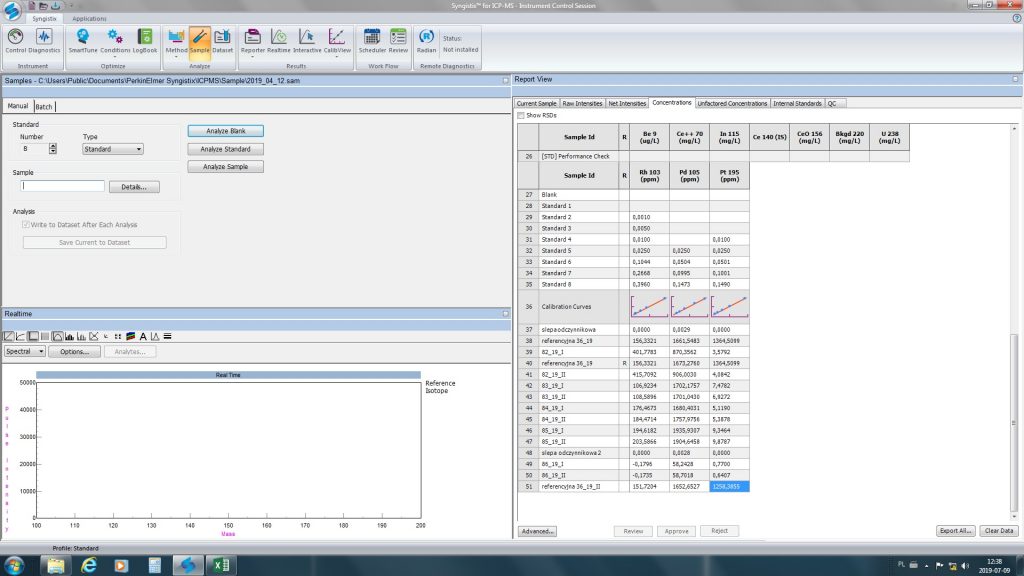

Of course, to perform a quantitative analysis, it is also necessary to properly prepare the apparatus, i.e. to find the relationship between the concentration / content of the element in the standard solution and the response of the detector. We therefore perform the calibration of the device. Based on the calibration results of the system and knowledge of the mass of the sample, which was taken to prepare the test solution – we are able to precisely determine how many individual elements are in the monolith. Our specialized analytical staff serves both a microwave mineraliser and an inductive excited mass spectrometer on a daily basis, performing tests and necessary maintenance activities to guarantee the correct operation of the equipment. We hope that today we briefly summarized the core of the analysis using the ICP-MS technique. We invite you to cooperation! Contact regarding the analysis using the ICP-MS technique – Tel. +48 730 016 017 or email michor@unimetalrecycling.pl